FIBERGLASS STRUCTURAL PRODUCTS:

DELTAPLATE & DELTAGRATE COVERED PLATE GRATING

Many applications require solid flooring for a variety of reasons, such as odor control in a wastewater plant, an offshore drilling mud room, or possibly for safety reasons to prevent small objects from falling through the floor to the level below. For these instances, AIMS offers two fiberglass plate grating solutions: DeltaPlate Structural Plate and DeltaGrate Covered Plate Grating.

TECHNICAL SPECIFICATIONS

PRODUCT DESCRIPTION

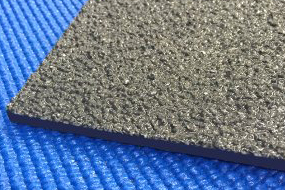

AIMS' DeltaPlate Structural Plates are offered in thicknesses ranging from 1/8” to 3/4”, and three choices of plate surfaces are available: checkered-top finish, gritted-top finish, or smooth-top finish. Thicker plates can be custom ordered. DeltaPlate is offered in all of the same resin systems as our DeltaGrate High Strength Molded Grating products and provide the same corrosion resistance features.

DeltaPlate fiberglass plate grating can be bonded to our DeltaGrate High Strength Molded Grating, creating a structural flooring that is 25-30% stronger than our standard DeltaGrate High Strength Molded Grating. DeltaGrate Covered Plate Grating offers all of the attributes as DeltaPlate, but with much higher load capacity. The standard thickness of the DeltaPlate utilized in the covered plate grating is 1/8”, however, customized thicker plates can be incorporated.

FIBERGLASS PLATE GRATING ADDITIONAL INFORMATION, BENEFITS AND FEATURES:

AIMS' corrosion resistant fiberglass products are found throughout the world in a variety of applications and industries where safety, low maintenance costs, easy installation, and long service life are essential.

CORROSION RESISTANT

Unlike conventional metals, AIMS products eliminate the rusting and corrosion problems associated with traditional materials. A proven pultrusion process, which combines fiberglass and proprietary resins, creates a durable and safer structure that outlasts metal, and offers a significantly lower life cycle cost. Additionally, special UV inhibitors included in the formulation provide extra protection from the effects of weathering.

EASY TO INSTALL, EASY TO MAINTAIN

There’s no need for heavy equipment or expensive tools since AIMS handrail and ladder systems are less than half the weight of steel. Lighter weight means lower shipping costs and less manpower for installation. With no scraping, sandblasting, or painting required, they are virtually maintenance free.

STRONG AND DURABLE

Pound for pound, fiberglass is stronger than steel. Plus, when designed to certain load-response criteria, FRP material will weigh one-third to one-half of its steel counterpart. Our handrails and ladders get their strength from a high percentage of glass within the laminate, providing durability, high unidirectional strength, and stiffness.

NON-CONDUCTIVE AND FIRE RETARDENT

AIMS handrails and ladders are electronically and thermally nonconductive, and are fire retardant for a safer work environment. Our products meet the self-extinguishing requirements of ASTM E-84, and have a Class 1 flame spread rating of 25 or less. Because our systems are non-metallic, electromagnetic and radio wave frequencies are completely unaffected.

A VARIETY OF COLOR CHOICES

The standard color for our handrails and ladders is Safety Yellow, but any system can be custom ordered to your specific color requirements.Quality Assurance All AIMS handrail and ladder systems are manufactured under a strict quality control program. This program coincides with our mission to offer the highest quality products and services and to continue to excel in research and development for new products.

SAFE SHIPPING

All orders are carefully secured and shipped on dedicated trucks to ensure on-time, damage-free delivery.

RECOMMENDED PRODUCTS

MOLDED FIBERGLASS GRATING

AIMS and Delta Composites, LLC, are partners in the manufacture of molded fiberglass gratings. AIMS’ Talon™ System has been developed and patented by AIMS International for the purpose of mechanically fixing the fiberglass grating system to the framing members of an offshore platform which are subjected to wave action.

PULTRUDED FIBERGLASS GRATING

AIMS’ DeltaSpan pultruded grating product offers excellent unidirectional strength and corrosion resistance. This product has been developed to meet specific requirements and is particularly suited for highly corrosive environments. It offers extended life and eliminates periodic maintenance and replacement costs making it the preferred alternative to conventional steel gratings.

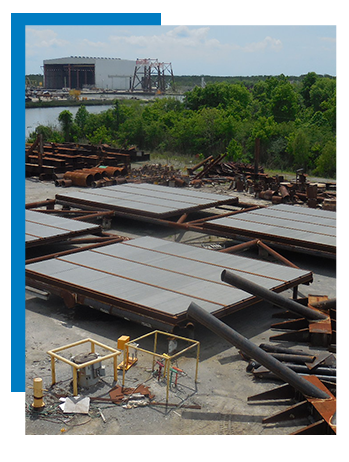

FIBERGLASS MUDMATS

One of AIMS’ newest products is its fiberglass mudmat system for offshore jacket structures. Our fiberglass mudmats are 24 times stronger than 1/4” steel plate and 7.5 times stronger than 3/8” steel plate. On average, this benefit eliminates half to two-thirds the steel filler beams necessary to compile a steel system. Furthermore, since the system is non-metallic it does not require cathodic protection.

PRODUCT LINKS