FABRICATION OF PLATFORM FENDERING SYSTEMS SOLUTIONS:

PLATFORM & DOCK FENDERING SYSTEMS

AIMS provides the design and fabrication of platform and dock fendering systems for the offshore oil and gas and refining industries. This product line consists of energy cells, boat landing rubstrips, barge bumper rubber sleeves, conductor stabilizers/centralizers, and custom rubber and urethane products.

TECHNICAL SPECIFICATIONS

PRODUCT DESCRIPTION

AIMS International provides the design and fabrication of platform fendering systems for the offshore oil & gas industry.

In 1992, AIMS acquired the Energy Products Division from Teledyne Monarch Rubber. This acquisition enabled AIMS to have the molds and tooling, as well as the intellectual property on the best offshore fendering product line in the industry. The Bond-In-Compression process utilized in the manufacturing of the AIMS energy cells allows for the most efficient and effective energy-absorbing cell in the industry.

SPECIFICATION

This product line consists of:

- Energy Cells (also known as “shock cells”)

- Boat Landing Rubstrips

- Barge Bumper Rubber Sleeves

- Conductor Centralizers (conductor stabilizers)

- Custom Rubber & Urethane Products

RECOMMENDED PRODUCTS

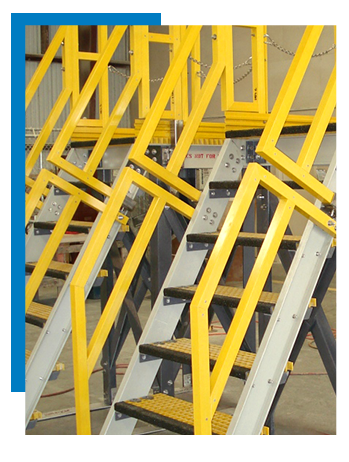

Fiberglass Handrail Systems

DeltaRail meets your requirements, from small platforms to complex structures, with high-strength, maintenance-free handrails that are ideal for any location.

Fiberglass Stair Solutions

AIMS' molded fiberglass stair treads are offered in two varieties: the DeltaTread and the DeltaGrate FabTread. DeltaTread stair treads are cut from DeltaTread panels measuring 22-1/4” x 10’-0”. The mesh of the DeltaTread is 1” x 6” with double bearing bars at the 6” intervals so that any stair tread with a length that is a multiple of 6” is always banded.

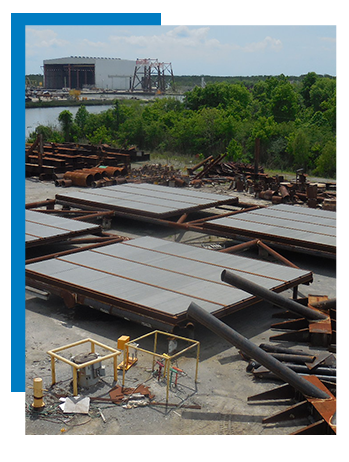

FIBERGLASS MUDMATS

One of AIMS’ newest products is its fiberglass mudmat system for offshore jacket structures. Our fiberglass mudmats are 24 times stronger than 1/4” steel plate and 7.5 times stronger than 3/8” steel plate. On average, this benefit eliminates half to two-thirds the steel filler beams necessary to compile a steel system. Furthermore, since the system is non-metallic it does not require cathodic protection.