AS LEADERS IN THE FRP INDUSTRY, WE ARE DEDICATED TO CUSTOMER SERVICE AND SUPPORT OF ALL MARKET SECTORS THROUGH CONTINUOUS ENGINEERING ADVANCEMENTS AND PRODUCT DEVELOPMENT. WE STRIVE TO PROMOTE AND MAINTAIN A SAFE, EFFICIENT AND COHESIVE WORK ENVIRONMENT THAT IS GOVERNED BY OUR CORE VALUES TO ENSURE THE BEST POSSIBLE OUTCOME FOR ALL.

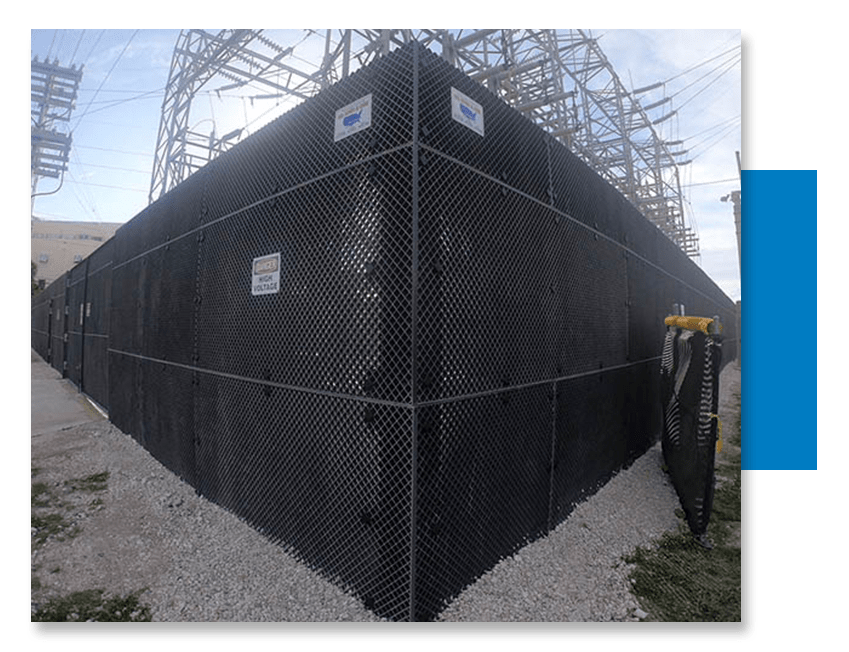

ENC SECURITY FENCING

AIMS' composite material is ideal for protecting critical assets, is electrically nonconductive (will not conduct electricity), is RF invisible with low radar reflectivity; which is great for Utility Transmission sites, Airports Security Perimeter Fencing and Telecommunication locations. FRP fencing can be used in place of metal fencing anywhere and is advantageous in areas with corrosion or conductivity concerns. The FRP fencing materials are fire retardant, non-corrosive, non-conductive, invisible to radar, and act as a visibility and security barrier.

FIBERGLASS STRUCTURAL PRODUCTS

Fiberglass structural systems consist of molded and pultruded fiberglass grating systems, access platforms, ladders, handrail systems, platform ID signs, and many other applications. Almost any structure that can be built in steel can be built with fiberglass by AIMS. AIMS employs a full staff of engineers and designers to create a finished product designed for the client’s custom application. AIMS is a world leader in engineered fiberglass structural systems and produces the most safe and cost effective fiberglass structures in the industry.

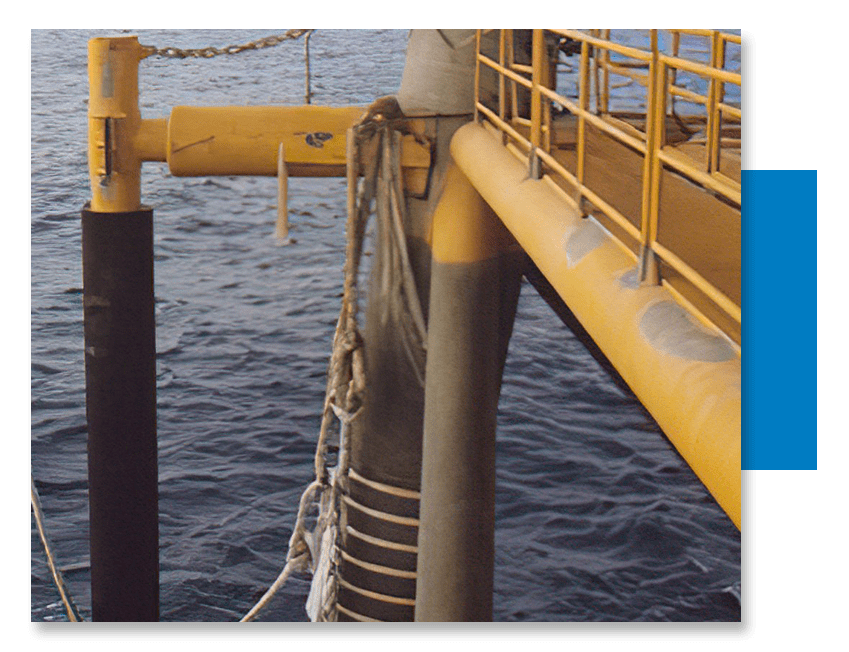

PLATFORM & DOCK

FENDERING SYSTEM

PRODUCTS

The purpose of a platform fendering system is to manage the kinetic energy transmitted from a berthing vessel to the jacket leg of an offshore structure. The kinetic energy is converted to potential energy and then back to kinetic with some minor losses (heat) that accelerates the vessel in the opposite direction. The reaction to that impact is managed by the energy cell at either end of the barge bumper system. The AIMS "TMR" Compression Bonded Energy Cells (formerly Teledyne Monarch Rubber) utilizes a manufacturing process that provides a constant bond-in-compression. This patented bond-in compression feature eliminates many of the problems associated with conventional energy cells, among them – poor rubber-to-metal bonding, limited axial and lateral deflection, and pullout.

Utilizing a superior grade of natural rubber in conjunction with the patented “bond-in-compression” manufacturing process, the AIMS "TMR" Compression Bonded Energy Cell is capable of greater deflection and higher energy absorption than conventional cells in both the axial and lateral modes. This is achieved through the design of the rubber annulus and the unique bonding process. .

VIV SUPPRESSION

PRODUCTS

AIMS provides a full line of vortex induced vibration (VIV) suppression products to the offshore oil and gas industry. This product line consists of both strakes and fairings. All of AIMS’ VIV suppression product designs are backed by full scale tank testing with Reynolds Numbers (Re) ranging from the low 1,000s to ~2,000,000. AIMS molds polyethylene into VIV suppression products allowing tight manufacturing tolerances, low drag coefficients, and high efficiency in VIV elimination.